Facilities

The workforce is constantly trained at our in-house training centre on generic parameters 4M, productivity enhancement and waste reduction techniques as well as specific customer requirements.

Our production plants are equipped with state of the art as well as customized manufacturing equipment suited for manufacturing products to customer requirements with the highest productivity and minimal fall out rates.

We are engaged in manufacturing prototypes through a dedicated industry slandered process thereafter being handed over to the mass production teams. We service our customers' high mix/low volume requirements as well as medium to high volume production batches.

Our highly flexible set up : dedicated work force and customer focused manufacturing teams make us a preferred destination, customers are most comfortable placing their manufacturing requirements with us since we work as their extended factories with the most transparent systems.

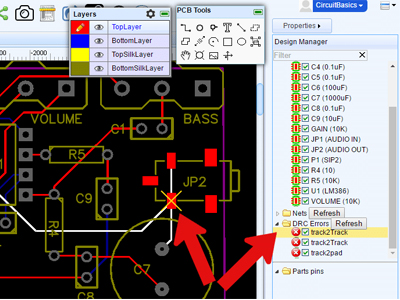

Proto type

Our quick-turn prototype service can be as short as 72 hours without sacrificing the quality. Our small run production ensures you the best combination of quality and cost effectiveness. We also support you to send these golden samples for a third-party testing facility for CE, UL, FCC and certification purposes for the ROHS markings Here we deliver satisfaction and not PCBA

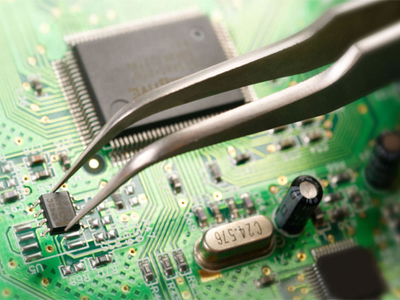

Rework / repair of PCBA

Dedicated skilled team equipped with required rework / repair set up . Ref standard – IPC7721

Electronic System solutions

- IOT & Industry 4.0 solutions

We offer variety of hardware combinations (Such as Various sensors, modules and peripherals) suitable for your machine integration and enhancement needs which enables one to quickly turn up high volumes of data into real-time knowledge based analysis We develop Machine to machine communication system that include sensors, RFID, a Wi-Fi or cellular communications link and autonomic computing software.

- Customised test systems , load boxes , breakout boxes & cable harnesses for automotive and non-automotive industry

- Customised automotive grade LCD modules and LED Backlights

- Inspection systems

We offer variety of hardware combinations (Such as Various sensors, modules and peripherals) suitable for your machine integration and enhancement needs which enables one to quickly turn up high volumes of data into real-time knowledge based analysis We develop Machine to machine communication system that include sensors, RFID, a Wi-Fi or cellular communications link and autonomic computing software.

- Customised test systems , load boxes , breakout boxes & cable harnesses for automotive and non-automotive industry

- Customised automotive grade LCD modules and LED Backlights

- Inspection systems

Concept to product

- 20 + readymade circuits ( Business ideas )

- 09 step product development mechanism – product concept , market analysis , product design and development , CAD / CAM , Proto type testing , manufacturing , assembly , feedback , final product

- 09 step product development mechanism – product concept , market analysis , product design and development , CAD / CAM , Proto type testing , manufacturing , assembly , feedback , final product

ESSCI Approved Training programs

We conduct Training programs to cater the skill needs of EMS industry

1. EMS Technician 2. Manual Insertion Operator 3. Quality Engineer.

1. EMS Technician 2. Manual Insertion Operator 3. Quality Engineer.

EMS Consultancy services

IATF 16949 Implementation, Third Party Audits, EMS Supplier Qualification Audits.

Battery recovery solutions

Newly developed robust & time tested device for regeneration / recovery of Lead-Acid Batteries

using electric properties ( pulses ) with new concept of controlled IT technology.

BATTERY REGENERATOR is the economic and eco-friendly "Green Energy" product. It regenerates

used or weak (run-down) batteries effectively with less processing time & without disassembling of batteries

using electric properties ( pulses ) with new concept of controlled IT technology.

BATTERY REGENERATOR is the economic and eco-friendly "Green Energy" product. It regenerates

used or weak (run-down) batteries effectively with less processing time & without disassembling of batteries